This generator sizing sheet will help you to determine your running and starting watts so you can choose the correct generator for your needs.

Electric motor size gearbox size chart.

Electric motors generators and drives the following are dimensional size charts for standard electric motor nema standard frames and configuration.

Gearmotor sizing guide.

1 5 safety factor 100 oz in.

C flange motors always have threaded mounting holes in the face of the motor.

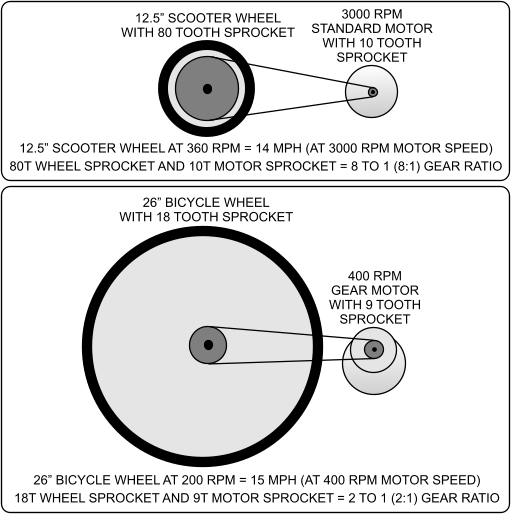

Recall that with a gearhead torque rises and output shaft speed drops with the gear ratio.

To use the chart find the point where 2 hp and 15 1 ratio intersect.

Once the gearbox is sized use the required hp to compute the actual service factor.

You can now size the gearhead to a motor by figuring 66 oz in.

80 100 7 9 20 iec63.

In this case that indicates a size 726 gearbox.

D the d flange face mounted motor.

80 100 7 m6 19 40 iec80.

The size of the generator you need depends on your power requirements.

Motor size spigot diameter a mounting hole pcd hc 2 mounting hole diameter d motor shaft diameter d motor shaft length l iec56.

70 85 7 m6 14 30 iec71.

On page 14 you will find a baldor frame size chart that is a great reference on t frame u frame and.

Calling motors with 2 digit frame sizes fractionals is somewhat.

John mazurkiewicz is a product manager with baldor.

This reduced rating based on the increased heat is.

Large hp motors generate heat that can adversely affect the reducer s mechanical ratings.

Generally a higher wattage generator lets you power more items at once.

Standardized motor dimensions are established by the national electrical manufacturers association nema are tabulated below and apply to all base mounted motors listed herein that carry a nema.

The critical items on c face motors are the bolt circle aj dimension rabbet diameter ak dimension and the shaft size u dimension.

The following specifications documents and dimension charts are available as acrobat pdf files.

Motor hp and frame size the gearbox size and input option must be determined before calculating the service factor.

This motor has a special type of mounting flange installed on the shaft end.

According to one manufacturer s product number system size 726 defines a gearbox that has a 2 62 center distance.

For the machine is 58 rpm and you were using a 1 750 rpm motor you would calculate gear ratio as follows.

60 75 6 m5 11 23 iec63.

For instance suppose that an application needs a 2 hp motor with a 15 1 ratio.

95 115 9 11 23 iec71.

110 130 9 14 30 iec80.