It should not be used if the coated part is expected to be exposed to direct sunlight for long periods of time as the coating will form a chalk like appearance under such conditions.

Epoxy polyester powder coating toxic.

Contrast this with wet paint which can be carcinogenic flammable and otherwise hazardous to employees if they do not handle it properly.

Epoxy paint contains toxic chemicals known as isocyanates that help to create this effect.

Exterior exposure can cause them to fade and chalk in the sun.

Tgic is known to cause skin sensitization in some people which can lead to severe skin rashes.

Epoxy powder coat one disadvantage of epoxy powders is their inability to weather well.

The powder particles which are charged stick to the electrically grounded surface before the powder is heated and then fused with a curing oven into a smooth coating.

When comparing polyester vs.

These isocyanate chemicals also create fumes that are dangerous when inhaled.

Respiratory sensitization is also a concern.

The drawback of epoxy powders is that they do not weather well.

In these evaluations the additive was blended with the epoxy powder coating via co fluidization in an air filled container.

The powder may be a thermoplastic or a thermoset polymer.

They can chalk and fade in the sun when subjected to exterior exposure.

Powder coating is a type of coating that is applied as a free flowing dry powder unlike conventional liquid paint which is delivered via an evaporating solvent powder coating is typically applied electrostatically and then cured under heat or with ultraviolet light.

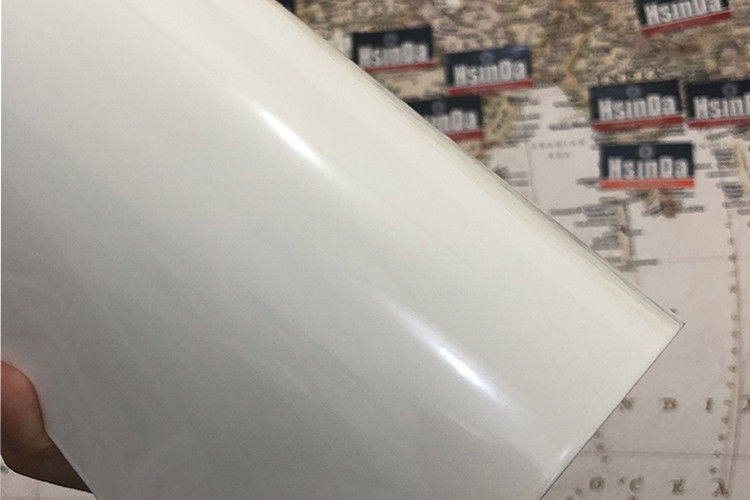

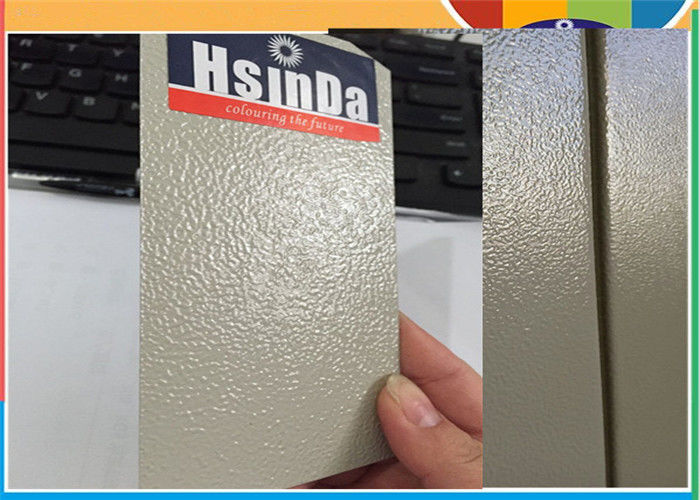

The finished product is a high quality durable attractive and uniform finish.

All our coatings are completely non toxic.

Excellent adhesion can be obtained through pretreatments of the metal involved including sandblasting and phosphate coating.

The finished product is a smooth glossy and durable surface that is easy to clean.

Amparmor 2000 has also been evaluated in a variety of standard epoxy powder coatings typically as part of a system incorporating a polyester topcoat.

During the preliminary phase of the work verincolor investigates which product is best suited to the substrate and any specific customer requirements.

Exposure occurs by breathing in dust containing tgic by skin contact and by ingestion.

As a result it is now classified as a toxin and cannot be used in certain regions.

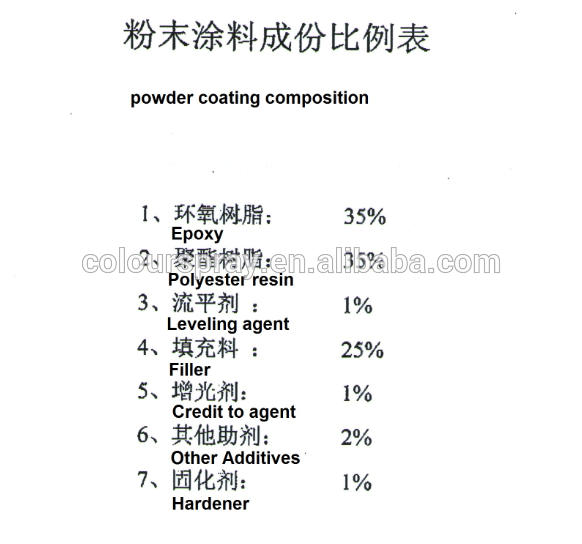

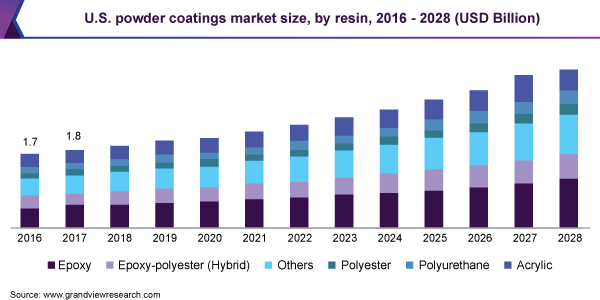

Coatings types and applications.

Polyester powder is widely used for decorative.

All of the powders used in powder coating processes are non toxic non volatile and completely safe whether they re being sprayed or simply sitting in one spot.